KSI Swiss Blog

What Medical Device Components Need in Early Design Stages

Designing medical device components starts long before any material is cut or machines are programmed. When we’re planning a part that needs to live inside a larger device (something that may be life-saving or life-supporting), every detail matters. We have to think ahead about how it’s supposed to work, where it fits, and how the…

Read MoreQuestions to Ask When You’re Considering Contract Manufacturing

Choosing contract manufacturing services can be a smart move when you’re short on time, staff, or in-house equipment. When done right, outsourcing can help you get high-quality parts while staying focused on other priorities. But the truth is, not all shops work the same way. Some use faster tools, some don’t. Some pay close attention…

Read MoreWhy Precision Machining Services Don’t Always Look the Same

At a quick glance, precision machining services might seem pretty similar no matter where you go. Parts go in, machines run, cuts get made. But what’s happening behind the scenes is anything but the same. When shops need to hit short deadlines, especially in high-pressure seasons like January, the small differences in how machines function…

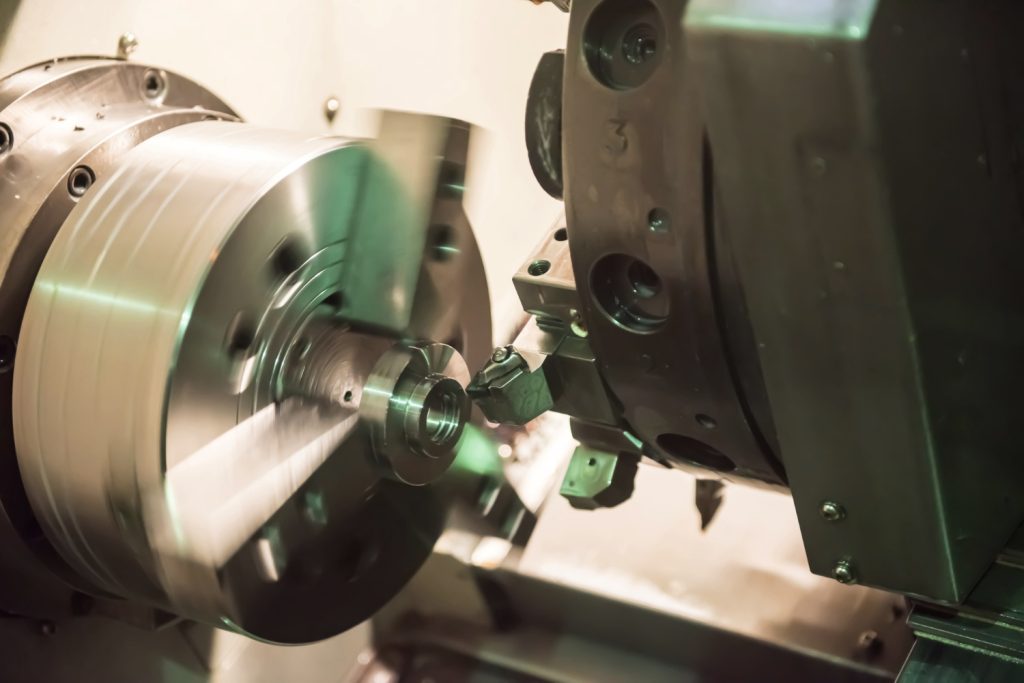

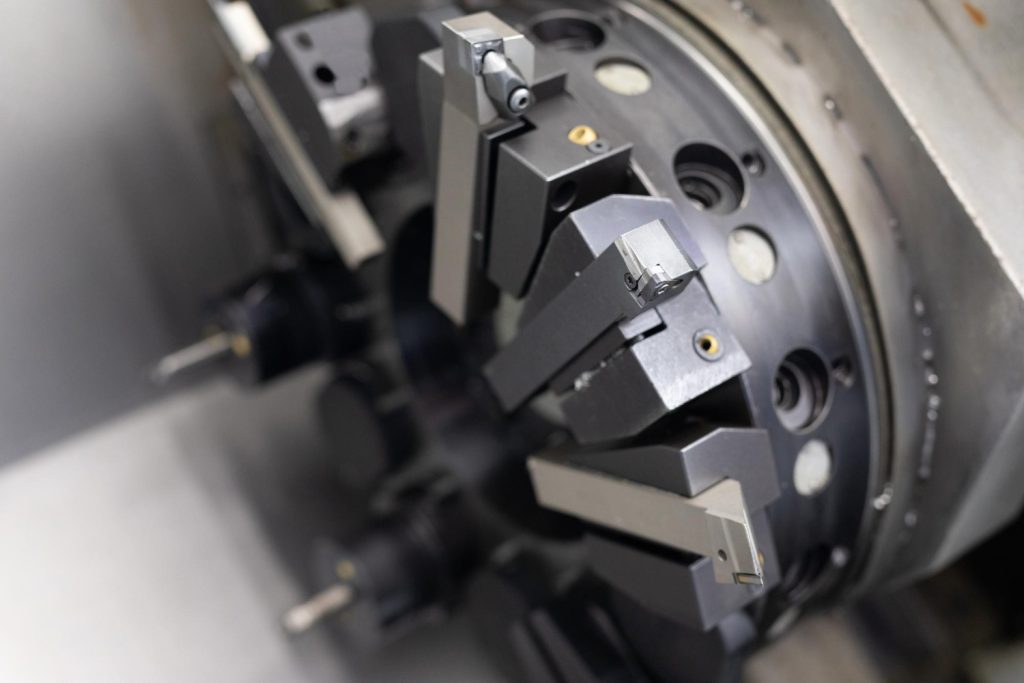

Read MoreHow Intelligent Chucking Speeds Up CNC Production Runs

CNC production runs can slow down for all kinds of reasons, but it often comes back to how much time is spent on setup and handling, not the actual cutting. Every stop, adjustment, or refeed eats away at the clock. With large orders and tight deadlines, especially in the winter push after the holidays, it’s…

Read MoreWhat Makes A Swiss Style CNC Machine Good for Tight Deadlines

Some production problems can’t wait. When orders spike or deadlines shrink, we can’t afford machines that slow things down. A good Swiss style CNC doesn’t just produce accurate parts, it keeps things moving when time gets tight. Jobs with short lead times need machines that start quickly, run efficiently, and don’t require constant adjustments. Late…

Read MoreWhy CNC Turning Services Can Help Short-Run Winter Jobs

During the winter months, machine shops often shift to shorter production runs. Some jobs may be smaller, more varied, or more time-sensitive as customers try to wrap up the year or prepare for the next one. That’s when things can feel busiest, even if the actual jobs are smaller. CNC turning services can really make…

Read MoreThe Role of Swiss-Style Lathes in Modern Manufacturing

Swiss-style lathes are a significant advancement in the manufacturing sector. Unlike traditional lathes, they deliver exceptional precision and detail. These machines effectively manage complex tasks with remarkable accuracy, essential in sectors needing flawless production. Whether crafting tiny components for watches or large parts for automotive industries, their versatility is evident. As manufacturers aim for impeccable…

Read MoreResolving Back-Working Operation Issues In Swiss Machines

Back-working operations play a major role in how well Swiss-style CNC machines perform. Done properly, they allow for the completion of complex parts in a single setup, cut down on total production time, and minimize handling errors. But when things go wrong at this stage, it can quickly lead to longer cycle times, inconsistent part…

Read MoreProper Setup Procedures For Swiss Lathe Operations

Swiss-style CNC automatic lathes are built for accuracy. When you’re working with tight tolerances or making high-quantity parts, even a small misstep in setup can ripple throughout the entire production run. Taking the time to set up these machines correctly isn’t just good practice. It’s the foundation for getting consistent, reliable results. Whether you’re producing…

Read MoreSetting Up Swiss Turning Machines for Optimal Performance

Setting up Swiss turning machines properly is like laying a strong foundation for a building. If the base is not solid, the entire structure is at risk. In the same way, ensuring the correct setup of these lathes is key to optimizing their performance and minimizing any potential downtime. Proper setup can lead to smoother…

Read More