Precision, intricacy, and speed – if these are the pillars of your manufacturing needs, the Swiss lathe may hold the key. Renowned for tight tolerances and multitasking efficiency, Swiss lathes stand as a pinnacle in high-volume, precision manufacturing. In the following sections, you’ll uncover the transformative impact of Swiss lathes in industries demanding exactitude without concession. Step into the realm of Swiss lathes where cutting-edge technology meets minute perfection.

Key Takeaways

- Swiss lathes are designed for precision, capable of machining intricate parts with tight tolerances, through a setup integrating various operations like milling and drilling.

- Swiss CNC lathes stand out through features like Intelligent Chucking and Rapid Tool Change, guide bushings for accuracy, and high-volume capabilities, which boost productivity and maintain quality.

- Swiss lathes are exceptionally versatile, suitable for a wide range of materials and industries, and can be tailored with attachments and tools for industry-specific needs, enhancing their indispensable role in precision manufacturing.

Unlocking the Potential of Swiss Lathes

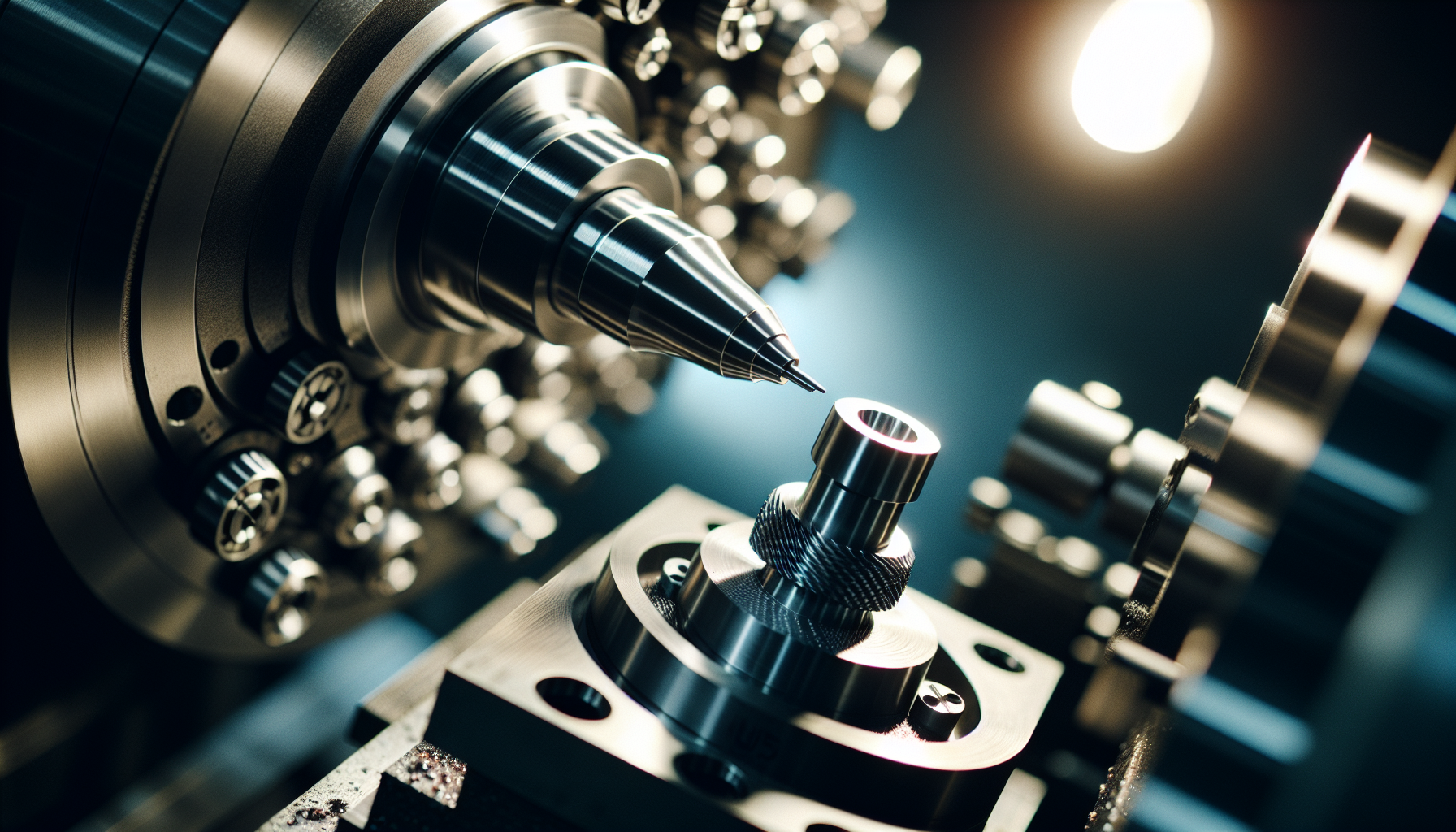

Swiss lathes are distinguished by their superior ability to produce small, complex components with strict tolerances. Their sophisticated structure is equipped with live tooling functions that facilitate finer and more meticulous cuts. This integrates additional machining operations such as milling and drilling smoothly into the workflow.

At the vanguard of Swiss machining, KSI Swiss boasts a comprehensive range of models known for expanding the limits of precision in machining. The product lineup includes:

- TCM series

- SII Type

- H Type

- HY2 Type

The Swiss Lathe Defined

Originating in the 1870s, Swiss type lathes were a significant advancement over traditional lathes, invented by Jakob Schweizer. They are renowned for their exceptional precision and feature several key characteristics.

- A headstock that advances metal stock through a guide bushing

- Cutting capabilities across multiple axes

- Achieving extremely fine tolerances down to ±0.0005 inches

- Capable of rotational speeds reaching 10,000 RPM

These Swiss type machines offer heightened efficiency by reducing the need for secondary finishing processes and exhibit greater versatility compared to conventional lathe machines with stationary headstocks.

Swiss Lathes vs. Conventional CNC Machines

Swiss lathes distinguish themselves through their stability in the machining process, resulting in minimal deflections and thus enhanced precision. This steadiness is vital when creating complex parts that require stringent adherence to tight tolerances. In contrast to standard CNC machines, Swiss lathes are capable of executing several operations simultaneously, reducing cycle times significantly and increasing efficiency—a particular advantage for high-volume production settings where precision is paramount.

Swiss CNC Lathes: A Technological Evolution

KSI Swiss stands at the forefront of technological innovation, integrating state-of-the-art elements like Intelligent Chucking and Rapid Tool Change in their Swiss CNC lathes. This integration promotes swift and accurate production processes while notably reducing setup times and augmenting the machine’s functionalities.

To guarantee unwavering quality control, KSI Swiss has equipped its CNC lathes with sophisticated monitoring systems. These systems are vital to sectors where elevated precision is a critical requirement and the margin for error is minimal.

The Role of Guide Bushing in Precision Machining

The guide bushing plays a pivotal role in ensuring the precision of Swiss lathes by offering essential support to the workpiece. This prevents any deflection that might adversely affect the accuracy of the cut. Its importance is amplified when dealing with slender workpieces, as it helps preserve roundness and adherence to dimensional tolerances which are at risk due to potential bending.

In producing components characterized by thin walls and intricate details, Swiss lathes equipped with guide bushings excel, delivering superior precision and finer surface finishes compared to standard machines.

Optimizing Production with High Volume Capabilities

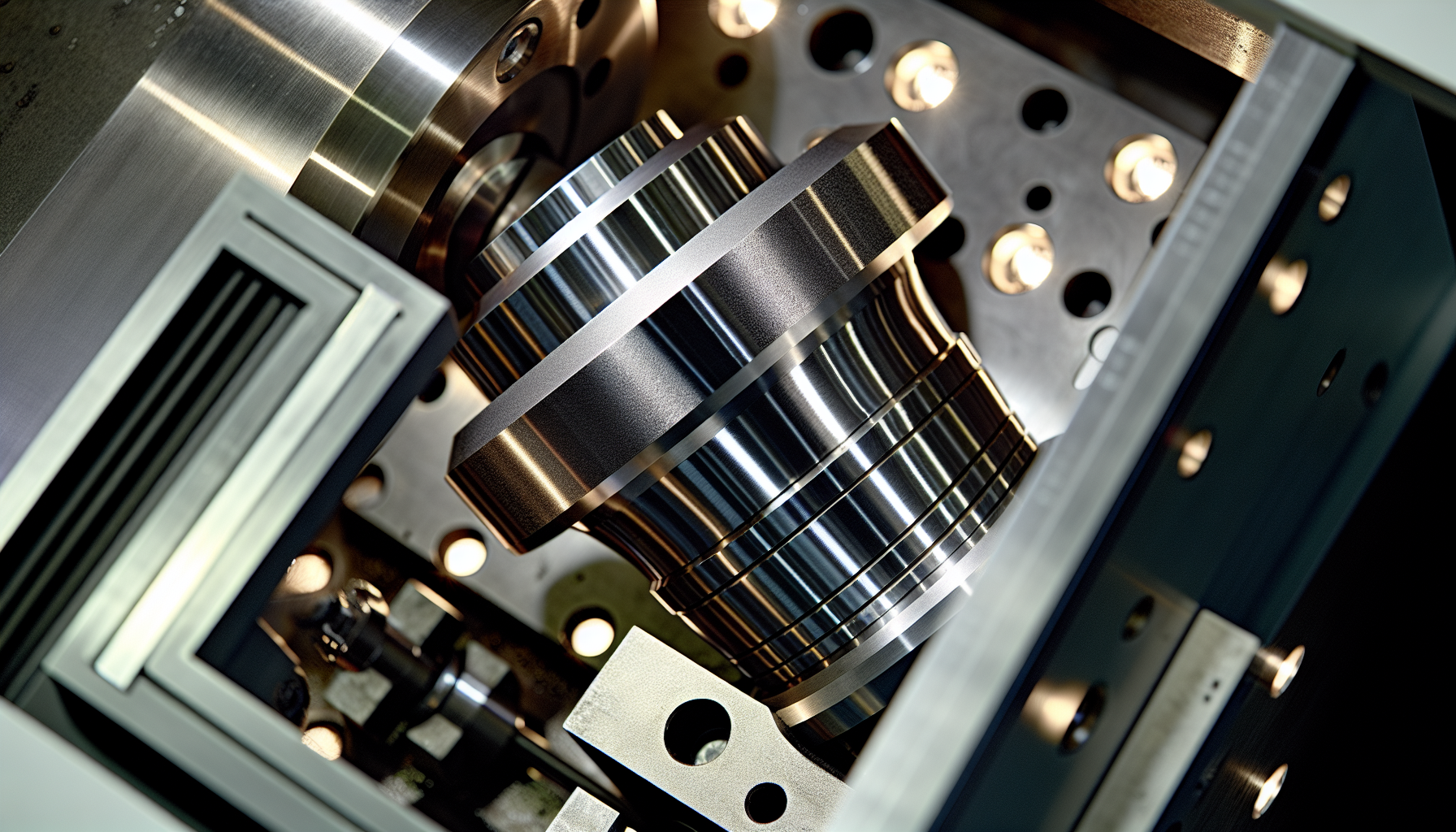

Swiss CNC machines stand out as productivity powerhouses, capable of operating with minimal oversight and churning out parts in cycle times frequently under a minute. These machines excel at managing high-volume production, which gives them an edge over comparable equipment.

The versatility of these CNC systems to hold more than 20 tools and perform intense cuts in just one pass while maintaining precision renders them perfectly suited for the fast and efficient fabrication of intricate components.

Materials and Industries: The Swiss Lathe’s Versatility

Swiss lathes are exceptionally adaptable, capable of shaping an extensive array of materials including diverse metals and hard plastics. They deftly work with the easy-to-machine nature of aluminum as well as the robustness and anti-corrosive properties of titanium, crafting parts that precisely conform to stringent specifications demanded by sectors such as aerospace, medical devices, electronics manufacturing, and automotive engineering.

From Bar Stock to Precision Parts

The modernization of the material supply chain through automated bar feeders has propelled Swiss lathes into an age of heightened productivity. Firms such as BarLoad and their collaboration with KSI Swiss have designed systems that effortlessly synchronize with Swiss lathes to maintain a consistent flow of bar stock, which is crucial for ongoing, large-scale manufacturing.

Such advancements culminate in machinery capable of producing intricate components replete with elaborate characteristics, including cross-drilled holes and milled slots—all within an impressively efficient framework.

Tailoring to Industry Needs

In sectors where precision is paramount, such as aerospace and the production of medical devices, Swiss lathes stand out for their versatility. These machines can be outfitted with unique attachments and instruments to tailor them for creating complex shapes and designs necessary in these industries, cementing their role as a vital asset within the manufacturing sphere.

KSI Swiss: Pioneering Swiss Machining Innovation

Having amassed more than thirty years of expertise, KSI Swiss has become synonymous with the superior quality associated with Swiss machining. Not only has it solidified its standing in manufacturing and design within the USA, but it has also launched groundbreaking innovations such as the Nexturn line, thereby cementing its role as a trailblazer in the sector.

Advanced Tech Center: Engineering Excellence

The Advanced Tech Center of KSI Swiss in Minnesota offers a suite of services encompassing distribution and engineering support to ensure customers receive an all-encompassing solution for their requirements in machining, rather than simply providing a machine.

The Swiss Machinist: Skilled Craftsmanship Meets Precision Technology

The Swiss machinist operates as an unseen artist, expertly maneuvering technology like Servo Learning Oscillation to govern chip formation and maintain superior production standards. This intricate interplay of proficiency and innovation guarantees that the components crafted meet stringent precision and quality benchmarks.

Investment Considerations for Swiss CNC Equipment

Considering the acquisition of Swiss CNC machinery necessitates meticulous thought. Businesses must balance various elements, including:

- The demand for high precision

- The complexity of the parts to be produced

- Economic efficiency considerations

- Expected volume of production

Swiss machines, and specifically those that are CNC-operated, represent a substantial capital outlay. This investment can lead to substantial long-term cost reductions and an enhanced quality in output.

Summary

Exploring the realm of Swiss lathes has revealed their exceptional precision and adaptability. KSI. Swiss shines brightly as a pioneer in this arena, delivering both the equipment and assistance required for various industries to fulfill the growing expectations for meticulous accuracy and productivity.

Frequently Asked Questions

What is a Swiss lathe?

A Swiss lathe utilizes a guide bushing to stabilize the workpiece, enabling machining operations that are both accurate and efficient by minimizing overhang or deflection of the part.

What is the difference between a Swiss lathe and a conventional lathe?

Swiss lathes and conventional lathes both execute subtractive machining processes, Swiss lathes differentiate themselves by utilizing mobile headstocks. These headstocks secure the workpiece and adeptly reposition it along the Z-axis during machining.

This capability enhances manufacturing efficiency and significantly improves precision in production tasks.

What is a Swiss lathe job description?

The role described entails managing a Swiss-type CNC lathe to precisely craft components by performing tasks such as drilling, cutting, and piercing raw materials in order to achieve the desired final shape of the product.

What makes Swiss lathes different from traditional CNC machines?

Swiss lathes set themselves apart from standard CNC machines by their capacity for high precision and adaptability. These sophisticated tools can execute various operations at the same time with enhanced stability, which in turn cuts down on cycle times and boosts productivity.