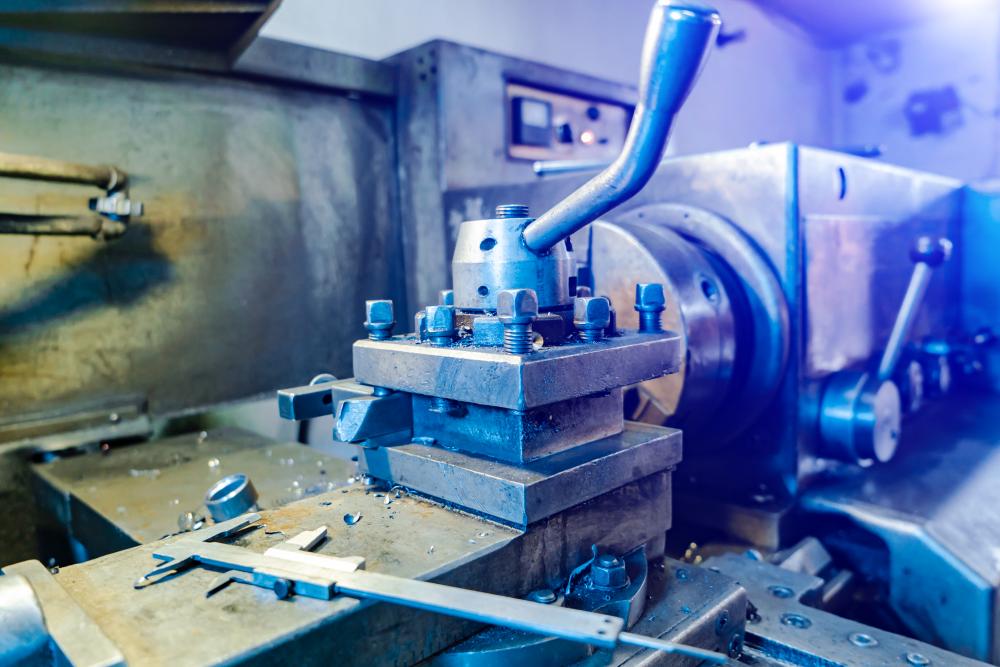

Swiss Lathe

Introduction to Swiss Lathes

At KSI Swiss, our journey into the world of precision and innovation began with a commitment to excellence in manufacturing Swiss-style CNC automatic lathes. The Swiss lathe, a marvel of modern engineering, stands at the forefront of our quest to deliver unparalleled quality and affordability to our customers. In this exploration, we’ll delve into the intricacies of Swiss lathes, showcasing their capabilities, benefits, and how they revolutionize industries by enhancing production processes.

The Evolution of Swiss Lathes

The inception of Swiss lathes traces back to the Swiss watch-making industry, where the demand for precision and intricacy was paramount. These machines have evolved from simple mechanisms to sophisticated CNC (Computer Numerical Control) systems, enabling the production of parts with unparalleled accuracy and speed. Our Swiss lathes embody this evolutionary spirit, offering features like intelligent chucking and rapid tool change to elevate machining precision.

Core Features of Swiss Lathes

Intelligent Chucking and Precision

One of the standout features of our Swiss lathes is intelligent chucking. This mechanism ensures that materials are held firmly yet flexibly, adapting to the specific requirements of each machining task. This, combined with high precision mode, allows for the machining of components with incredibly tight tolerances, a necessity in industries like aerospace and medical device manufacturing.

High Productivity and Efficiency

The efficiency of Swiss lathes is unmatched. With capabilities such as rapid tool change and variable frequency turning, our machines minimize downtime and increase throughput. This efficiency is a game-changer for manufacturers aiming to scale their production without compromising quality.

Advantages of Swiss Lathes

The Swiss lathe is not just another piece of machinery; it’s a conduit for precision, speed, and versatility. The design allows for the simultaneous performance of multiple operations, drastically reducing production time while maintaining exquisite detail in every part produced. The ability to hold tight tolerances and produce complex geometries makes the Swiss lathe an invaluable asset in any high-precision manufacturing environment.

Applications in Various Industries

Swiss lathes have broadened their reach far beyond the watch-making industry. Today, these machines play a crucial role in the medical, aerospace, automotive, and electronics sectors. They are pivotal in the manufacture of intricate components such as dental implants, aerospace connectors, automotive injectors, and electronic micro-components.

Choosing the Right Swiss Lathe

When it comes to selecting a Swiss lathe, the choice revolves around understanding your specific manufacturing needs. At KSI Swiss, we offer a diverse range of Swiss-style CNC automatic lathes, catering to various industry requirements. From deciding between 7 and 8 axis options to considering the machine’s range (20 mm to 38 mm), our team of experts is here to guide you through the selection process, ensuring you find a machine that aligns with your production goals and budget.

Advanced Capabilities

Our commitment to innovation is reflected in the advanced capabilities of our Swiss lathes. The addition of Live Tool Options, such as face slotting units and slitting saw units, extends the versatility of our machines, allowing customers to undertake a wider range of machining operations with a single setup. This adaptability not only enhances productivity but also opens avenues for creativity and innovation in manufacturing processes.

Unmatched Customer Support

We understand that purchasing a Swiss lathe is a significant investment. That’s why we’re dedicated to providing comprehensive support, from helping you find the right distributor to offering ongoing technical assistance. Our team is committed to ensuring that you maximize your investment and achieve your production objectives.

Embracing the Future with Swiss Lathes

The Swiss lathe represents more than just technological advancement; it embodies a commitment to precision, efficiency, and innovation. At KSI Swiss, we’re proud to lead the charge in the evolution of Swiss-style CNC automatic lathes, providing our customers with machines that promise not just to meet but exceed their manufacturing requirements. As we look to the future, we remain dedicated to enhancing our products and services, ensuring that we continue to offer solutions that cater to the ever-evolving needs of the industry.

What is a Swiss lathe?

Imagine you’re looking through a microscope to create a masterpiece, where every detail matters. That’s what operating a Swiss lathe feels like. A Swiss lathe, often hailed from the precision-driven watch-making industry of Switzerland, is a type of CNC (Computer Numerical Control) lathe designed to craft small, intricate parts with unmatched accuracy. Here at KSI Swiss, we’ve honed this technology to ensure that every turn, cut, and mill meets the high standards of industries requiring microscopic precision, like aerospace and medical devices. What sets Swiss lathes apart, is their capability to support the workpiece with a guide bushing, offering stability that translates into the ability to achieve tight tolerances on slender, elongated components.

What is the difference between a Swiss lathe and a conventional lathe?

Conventional lathes have been the backbone of machining for centuries, known for their robustness and versatility. However, when precision and intricacy enter the conversation, Swiss lathes steal the spotlight. The primary distinction lies in their operation mechanism. In a Swiss lathe, the workpiece is fed through a guide bushing, offering exceptional control and stability, allowing for machining with minute tolerances. This mechanism is pivotal for industries where a micron-level misalignment could mean failure. On the other hand, conventional lathes hold the workpiece in a chuck or between centers, ideal for larger, less intricate projects. It’s like comparing a scalpel to a sword; both are essential in their domains.

What is a Swiss lathe job description?

A Swiss lathe operator is akin to a maestro, orchestrating a symphony of precision cuts and movements. The role involves setting up, operating, and maintaining the high-tech Swiss CNC machines that produce the tiny, complex parts essential in modern technology. It’s not just about feeding metal into a machine; it’s about understanding the material, the tools, and the software to produce pieces that often go into life-saving medical devices or aerospace components. Every day presents a new challenge, requiring a blend of technical knowledge, attention to detail, and a passion for precision. At KSI Swiss, equipping our team with the skills and understanding of Swiss lathes ensures that innovation never stops.

What is the difference between CNC and Swiss CNC?

In the world of machining, CNC stands as a cornerstone technology, enabling the automated control of machine tools with high precision and repeatability. Swiss CNC is a specialization within this realm, embodying the pinnacle of precision machining. While conventional CNC machines excel in producing a wide range of components, Swiss CNC lathes specialize in ultra-precise, small-scale production. The distinction is not just in scale but in complexity and efficiency. Swiss CNC machines can perform multiple operations simultaneously – turning, milling, drilling, with minimal interference, making them indispensable for sectors demanding microscopic accuracy and intricacy. It’s the difference between a skilled artisan and a master craftsman, each valued but serving different purposes.

What are the advantages of intelligent chucking in Swiss lathes?

Intelligent chucking in Swiss lathes is like having a smart assistant that perfectly grips and adjusts to each unique piece being machined. This feature is critical for ensuring that delicate, often expensive materials are handled with the utmost care, minimizing waste while maximizing precision. The adaptive grip provided by intelligent chucking systems permits our Swiss lathes to maintain their characteristic precision across a diverse range of tasks, from creating the smallest medical implants to intricate aerospace components. This versatility not only improves productivity but also encourages innovation, as manufacturers are less constrained by the limitations of their machinery. At KSI Swiss, intelligent chucking is a cornerstone of our commitment to delivering machines that meet the versatile needs of modern manufacturing.

How do I choose the right Swiss lathe for my manufacturing needs?

Choosing the right Swiss lathe is akin to selecting the perfect tool for a master artist – it must match your creative vision and the specifics of your project. At KSI Swiss, we understand that every manufacturing operation has unique requirements. Factors to consider include the complexity of the parts you’re producing, the materials you’re working with, and the volume of production. Our range of Swiss-style CNC lathes offers versatility, from 7 to 8 axis configurations, catering to both intricate designs and efficient production runs. We encourage potential customers to engage with us, sharing their challenges and aspirations. This collaborative approach allows us to recommend the most suitable machine, ensuring it not only fits your current needs but also accommodates future growth and technological advancements. Remember, investing in a Swiss lathe is not just about acquiring a piece of machinery; it’s about empowering your manufacturing process with precision, efficiency, and innovation.

Resources

- Swiss Mechanism Organization – The Swiss Mechanism Organization offers a comprehensive guide to Swiss lathes and their applications in various industries.

- Medical Device Education – Learn more about the use of Swiss lathes in the medical device manufacturing industry and their importance in producing intricate components like dental implants.

- Aerospace Industry Education – Explore how Swiss lathes are utilized in the aerospace industry for the production of precision components like connectors.

- Automotive Engineering Resources – Discover the role of Swiss lathes in the automotive sector, particularly in manufacturing components such as injectors.

- Electronics Manufacturing Education – Dive into the world of electronic micro-component production with Swiss lathes and their impact on the electronics industry.