KSI Swiss TCM H Type Series

TCM 32H / 38H

Seven-Axis

Greater flexibility for complex parts

Easy Access

Generous openings for fast machine setups

More Mass

Rigid & stable casting for higher tolerances

Looking for a Proposal?

We've got several machines in stock and ready to be delivered and installed quickly. Reach out to us today to request a proposal. You'll be glad you did!

The More Factor. More

Intelligent Chucking

Intelligent Chucking takes advantage of the ample 300-millimeter stroke to reduce the number of bar re-chucks during long production runs. Instead of rechecking for each part, the spindle feeds 280 millimeters of material to make multiple parts in a single chucking operation and increments forward for each part. See how this can shave even more off your cycle time.

High Precision Mode

Our CNC Swiss Lathes in Lakeville MN’s High Precision mode add even more stability by minimizing vibration caused by high-speed movements of the tool blocks. By reducing the acceleration and deceleration of the axis motors, a smoother movement is achieved. Less vibration and fewer jerky movements to the axis allow the machining of mirror-like finishes with one tool while simultaneously performing coarser operations such as threading with another tool

Tool Life Management

Traditional tool life management protocols require a machine to be shut down and serviced when a tool is worn or no longer performs to spec tolerances. Often, other tools were replaced at the same time, even if not fully worn out, to avoid shutting down again a short time later. KSI Swiss automatics take tool life management a step further.

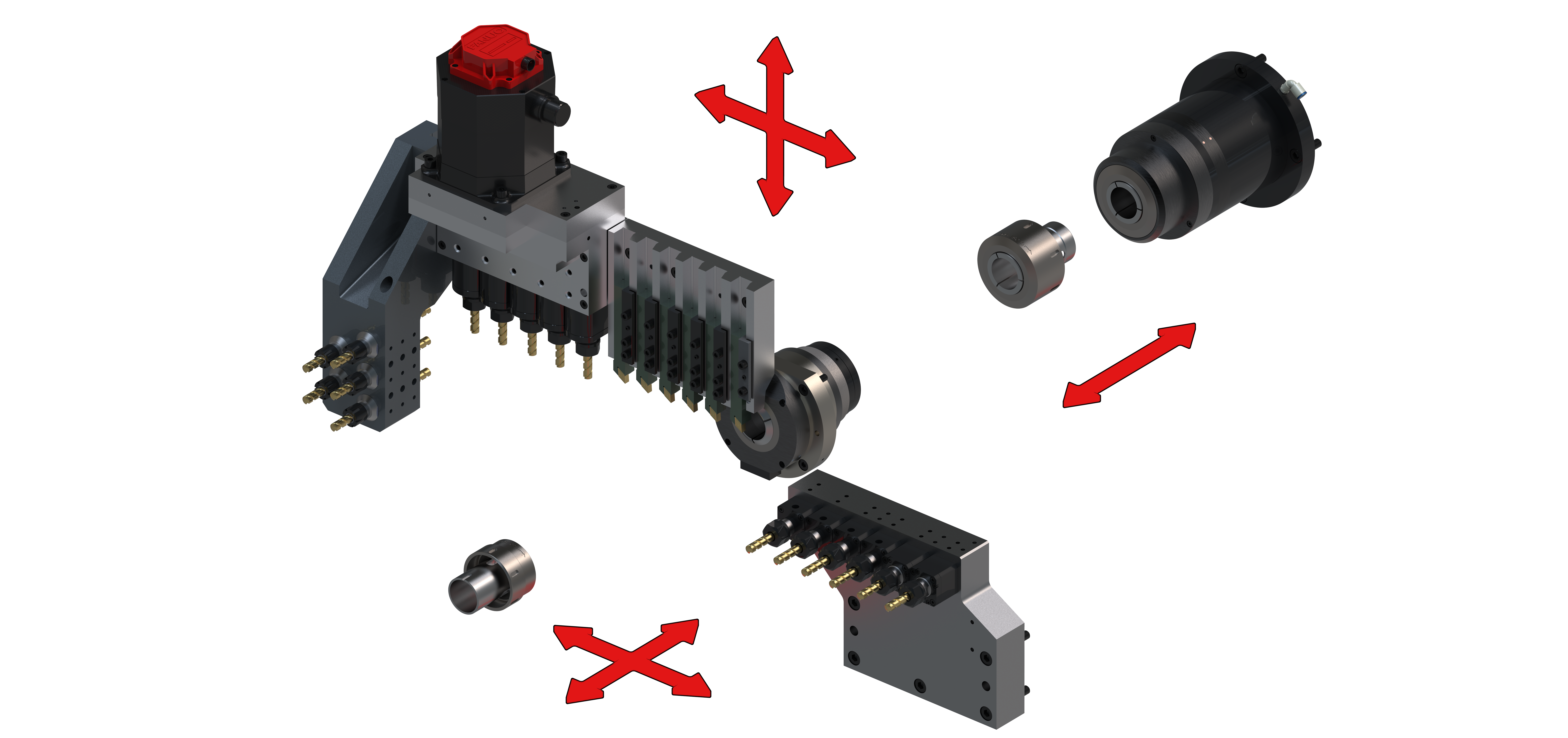

Rapid Tool Change

Our Rapid Tool Change feature shaves cycle time by moving the tool in a smooth arc instead of moving fully back, over, and up for each tool change. The software calculates the smoothest and most efficient transition path from tool to tool saving time on every tool change. Savings that add up to a significant reduction of cycle time, which means more profits for you.

Variable Frequency Turning

Variable Frequency Turning (VFT) uses a modified sine wave equation to move the cutting tool at varying intervals to allow for greater chip thinning and chip breakage. This allows for better heat dissipation, chip control, and less machine downtime for taking care of chip issues.

Machine Dimensions

A: Length (mm) 3,130

B: Height of Center (mm) 1,060

C: Height (mm) 1,785

D: Distance of Center (mm) 600

E: Width (mm) 1,470

Weight (kg) 4,500

All specifications are subject to change without notice.

Machine Stroke